CAST FILM EXTRUSION

RESEARCH & DEVELOPMENT

Research & Development lies at the very heart of our activity. We work in close collaboration with our customers and suppliers of raw materials and machines while drawing on our extrusion know-how.

The company is able to offer you highly technical film solutions.

CAST Extrusion

To extrude a thermoplastic polymer, granules are fed into a heat-regulated cylinder inside which an endless screw is turning. Due to the combined effect of the kneading action and heat, the granules are turned into a homogenous mix looking like a paste which is then given the desired shape by the die.

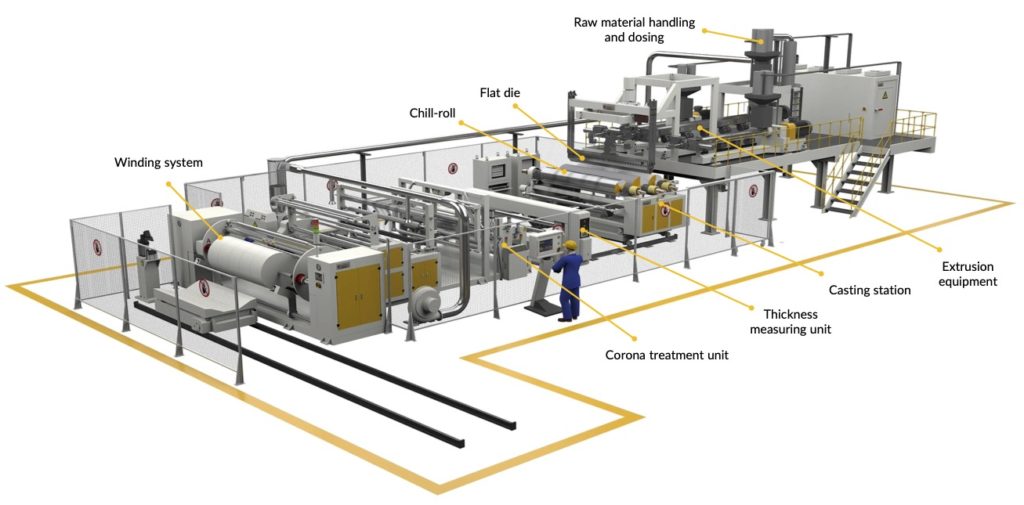

CAST extrusion line