PROPYPLAST will participate in the trade fair LABELEXPO Europe from 16th to 19th September 2025 in Barcelona, Spain.

LABELEXPO Europe is the world’s largest event for the label and package printing industry. With more than 35 000 visitors and 630 exhibitors from 138 countries, LABELEXPO Europe trade fair has become the leader in this sector.

We will be delighted to welcome you on our booth, the L93, in order to present you our products and our latest developments.

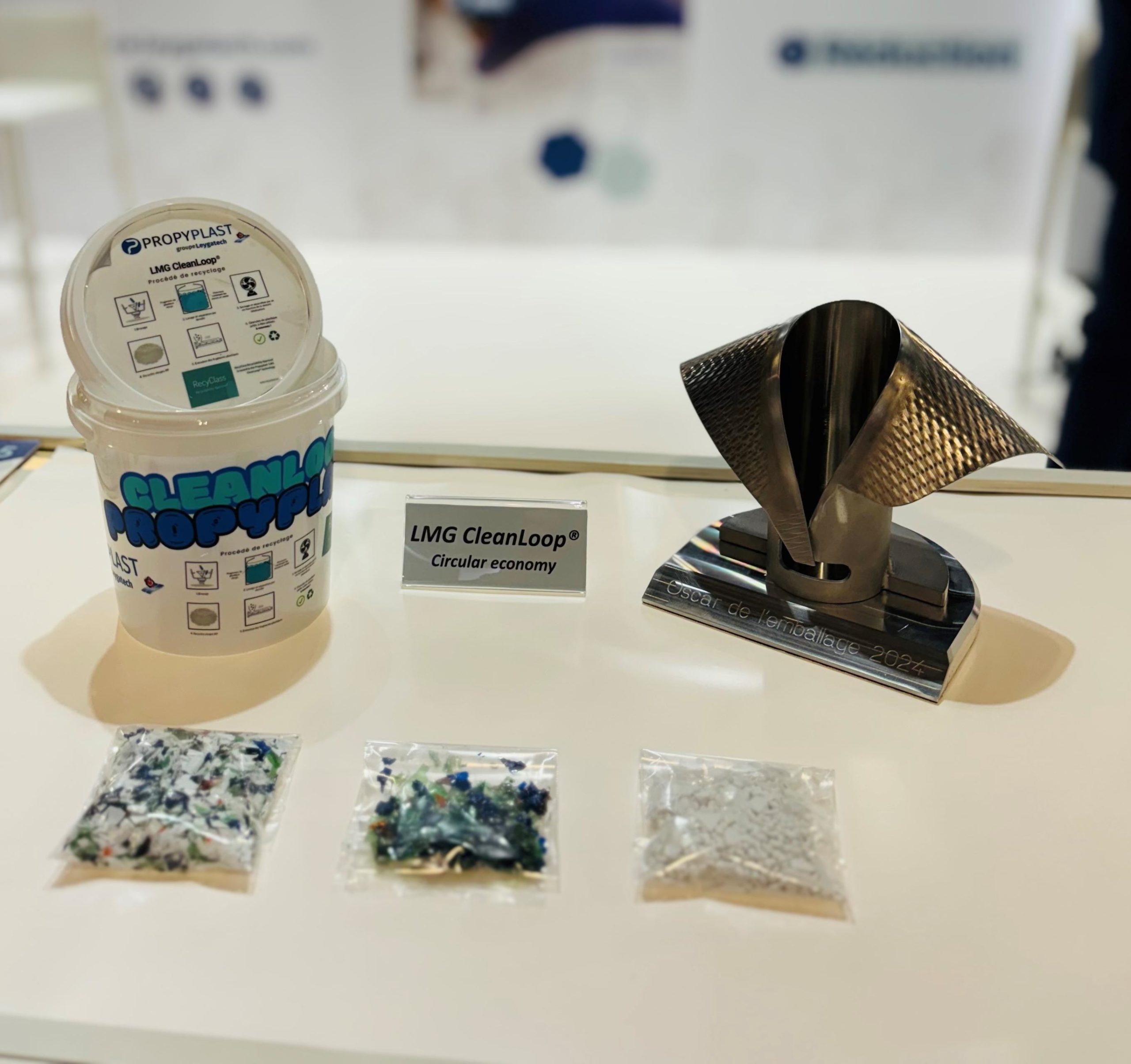

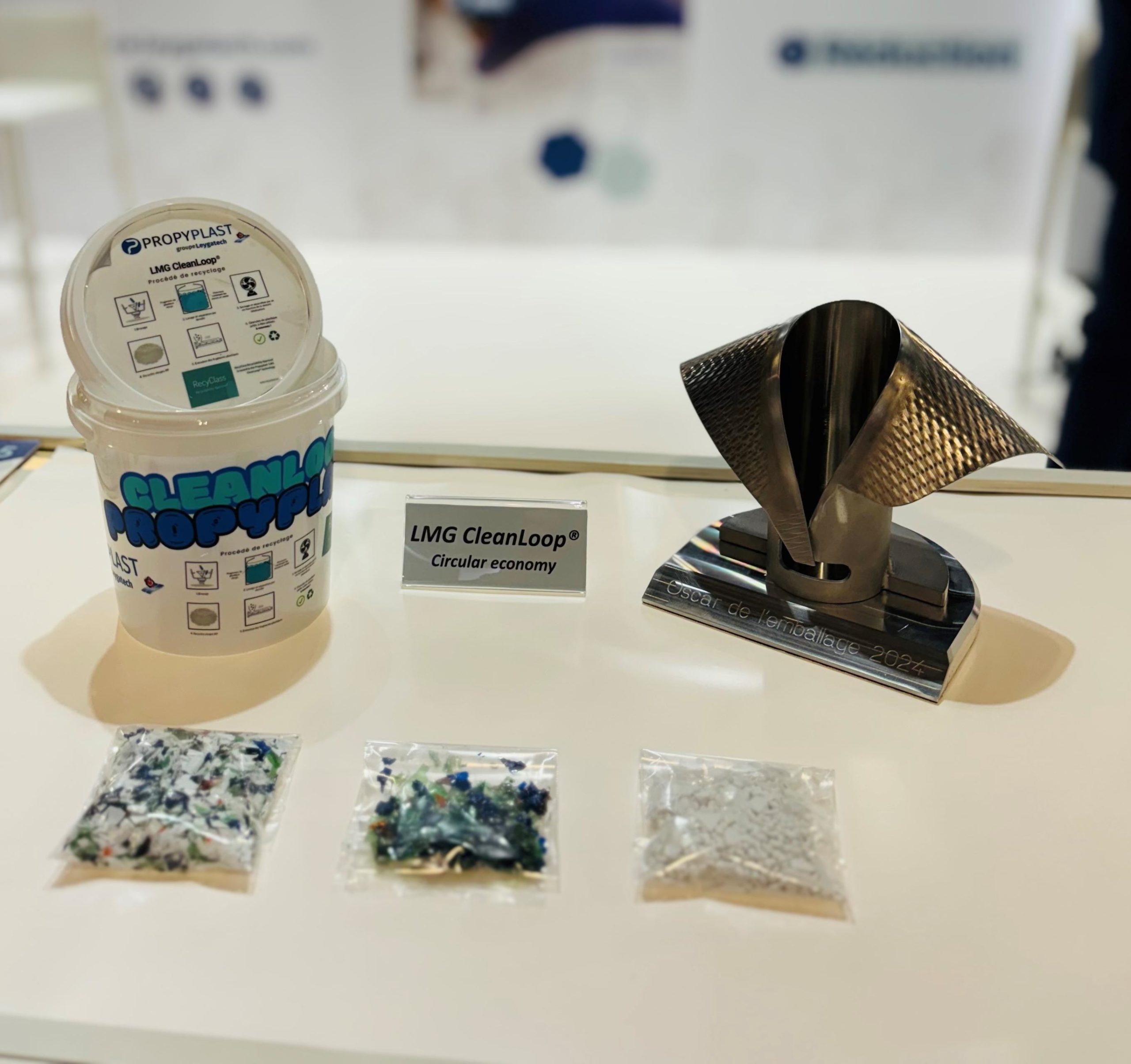

We are proud to announce you that we won two prizes at the French ceremony “L’Oscar de l’emballage 2024” (i.e. the 2024 packaging award) for our latest development called the LMG CleanLoop®!

The first prize was for the plastic transformation category and the second one for the zero impact packaging.

The LMG CleanLoop® offers to the IML industry a solution allowing a 100% recyclability of containers with IML. The particularity of this film is the separation, during the crushing phase, of the printed layer from the rest of the label and the container.

We have obtained the RecyClass approval for the LMG CleanLoop® which confirms that this film is fully compatible with the PP recycling stream, thanks to a reincorporation of the recycled material up to 100%.

The PROPYPLAST team is delighted to announce the launch of a new IML film range, whose registered trademark is LMG CleanLoop®.

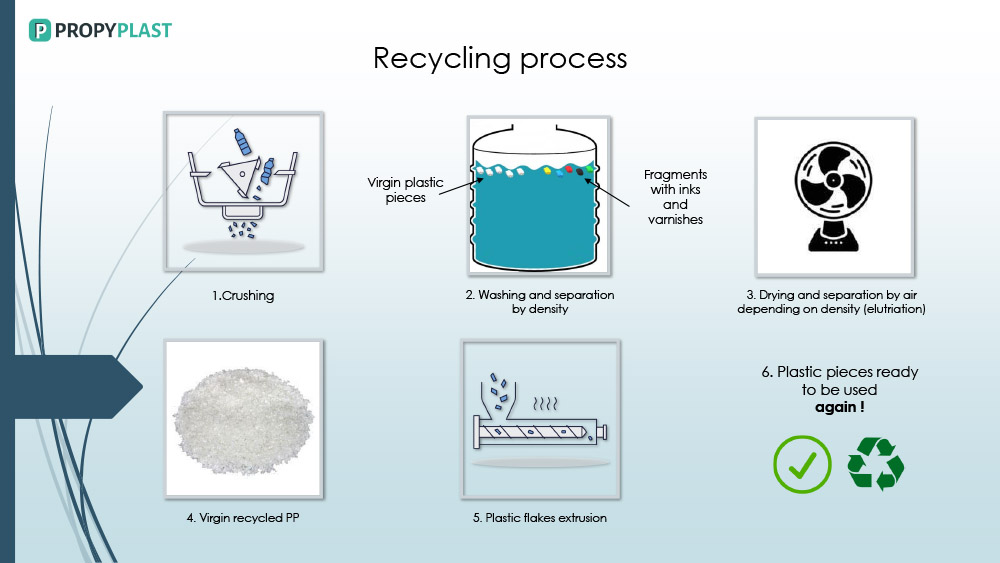

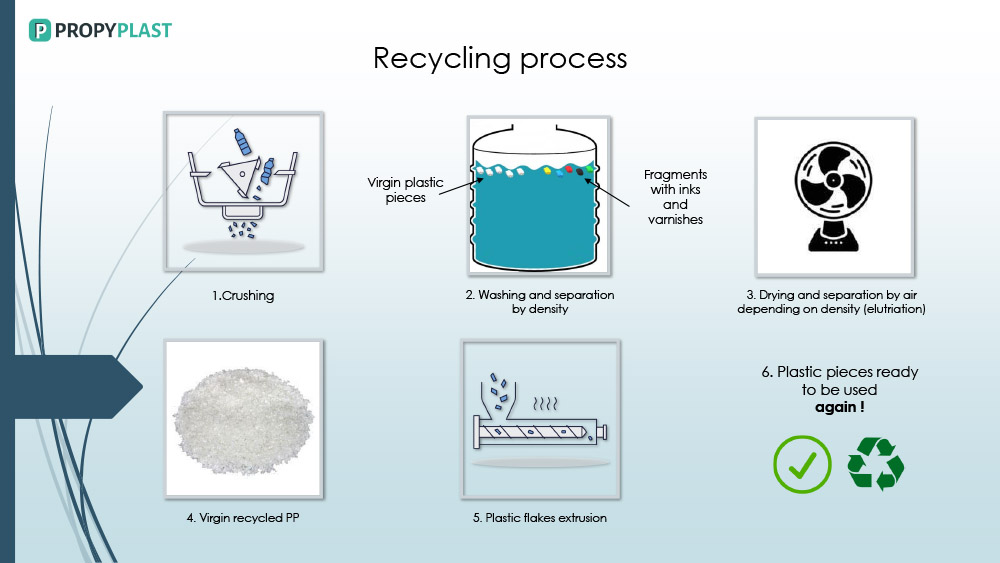

The presence of inks and varnishes in PP packaging with IML is currently causing trouble within the recycling industry, as the quality of the recycled material prevents its reuse without a loss to the PP value. Thus, our objective is to find a solution to this problem thanks to our new film, the LMG CleanLoop®.

The LMG CleanLoop® solution is characterized by the separation, during the first phase of crushing, of the printed layer from the rest of the label and the white or clear container, which enables obtaining a virgin PP recycled material.

To better understand the recycling process of this kind of film, you will find below a detailed diagram:

This film is an interesting solution for both the recycling industry but also for injectors who will be able to add value to their own production waste.

All these characteristics have enabled us to obtain the RecyClass approval for the LMG CleanLoop® which confirms that this film is fully compatible with the PP recycling stream, thanks to a reincorporation of the recycled material up to 100%.

Link to the RecyClass approval for the LMG CleanLoop®:

https://recyclass.eu/news/recyclass-recyclability-approval-is-issued-to-the-propyplast-lmg-cleanloopr-technology/

If you want more details, please contact us:

– Via the contact form present on our website.

– By phone at +33 (0)4 71 657 555.

PROPYPLAST recently developed a PP CAST film for peelable liddings, whose registered trademark is LIDPIL®.

The goal is to offer a 100% monomaterial solution ahead of non-recyclable multimaterial products.

This main characteristic allows the LIDPIL® film for peelable liddings to obtain the A RecyClass distinction, stating that it is 100% recyclable.

Moreover, the LIDPIL® carbon footprint is very positive compared to the other solutions currently used (on aluminium basis).

Our LIDPIL® product range is made up of different films for peelable liddings: clear, white, with or without oxygen-barrier property.

It is possible to propose LIDPIL® with other barriers (light, UV) and to include different barriers within the same film.

If you want more information, you can:

– Visit our website page dedicated to this product

– Contact us directly.

Labelexpo Europe is the world’s most important event for the label and package printing industry.

Around 40,000 visitors from 140 different countries participate in this trade fair in order to see the latest novelties of this sector.

This trade fair will take place in Brussels (Belgium) from 26th to 29th, April 2022.

Our stand number is 4E18 and we will be delighted to see you for presenting you our products and latest developments.

If you want to meet us for a project, do not hesitate to schedule an appointment by contacting us via the contact form present on our website.

Propyplast has obtained the FSSC 22000 certification (Version 5.1 – November 2020), result of a long work and an ever stronger commitment towards current stakes.

This standard relies on a detailed danger analysis within a food security management system in order to control those threats, to minimize risks and to ensure the production of safe packaging and packaging materials.

This program uses international norms such as ISO 22000 for food security management.

As a link within the food-processing industry and thanks to its FSSC 22000 certification, PROPYPLAST reinforces its customers’ trust and shows its skills for danger management in order to guarantee safe production and product delivery worldwide.

A few years ago, Propyplast developed a PP CAST film for IML with the following antimicrobial

properties:

- Staphylococcus aureus (Gram +)

- Escherichia Coli (Gram -)

This film is called LMG® C ANTIMICROBIAL.

The development and proliferation of bacteria on the surface of the film are slowed down and the number of microbes and bacteria is strongly reduced and proven according to ISO 22196 :2011.

Recently, independent trials (ISO 21702 standard) using the E229 Human Corona virus (strain virus of Covid-19) have proven that this technology reduces the virus 5 times faster than on normal solid plastic surfaces.

Without any toxic substance nor migration, properties, transparency and recyclability of the film remain unchanged. Our film, complying with the 10/2011 (EU) Regulation, is adapted to direct contact for food applications. In addition, the absence of migration guarantees functionality over time. This virucidal and bactericide solution therefore offers an efficiency not only against adhesion and proliferation of bacteria, but also against viruses.

Tests were carried out with the Coronavirus E229 for the following reasons:

- Tests with the virus causing Covid-19 are prohibited for commercial laboratories

- The Coronavirus E229 presents great similarities with the SARS-CoV-2 virus responsible for

Covid-19.

Thus, we can use our experience in the manufacture of our virucidal and bactericide IML film to develop similar solutions in other scopes of application where we can also offer an intrinsic resistance to bacteria, mould, fungi and viruses.

Please do not hesitate to contact us!

Download the technical sheet

The LMG® product range has been updated in order to satisfy customer’s needs regarding IML applications.

As a proof of its adaptability and reactivity capacities, PROPYPLAST is the first French company to obtain the ISO 22000 certification of the 2018 version.

Our certifications >

IML film with a metallic aspect that presents the same injection and printing properties as the LMG® range:

– Film with a metallic finish

– Positioning in the mould is carried out via electrostatic charge rather than vacuum

– Same unstacking and adhesion qualities as the standard LMG® range

– No distortion in the case of application to lids

– The product is entirely recyclable